Choose a tray or packing and divide number of equilibrium stages by tray efficiency to get actual. The feed gas composition is specified. Absorption column design calculations.

Absorption Column Design Calculations, Distillation and absorption are two most widely used mass transfer processes in chemical industries. Staged columns and other continuous ie. 106-5 or 106-6 5. 07022020 Due to receipt of continuous requests for the blower capacity hydraulic power estimation Flooding HETP calculations extending the post.

Mod 04 Lec 02 Packed Tower Design Part I Youtube From youtube.com

Mod 04 Lec 02 Packed Tower Design Part I Youtube From youtube.com

The Temperature and pressure of the inlet feed gas and column is specified. F ACETONE ABSORPTION COLUMN Required. Graphical Method to Find Equilibrium Stages for Absorption Columns equilibrium constant mole fraction in gasmole fraction in liquid liquid flow rate mol time-1 liquid flow rate on a solute-free basis mol time-1 total number of stages. ACETONE ABSORPTION COLUMN CALCULATION REPORT TECHNOLOGICAL AND CONSTRUCTION PROJECT EQUIPMENT ACETONE ABSORPTION COLUMN Nomenclature.

The equilibrium x y data are converted to mole ratio unit X Y and plotted on X-Y plane.

Read another article:

Select a suitable packing material with F p random or structured 2. 32 Schematic of adsorption column L qA q flow rate u volumetric flux or Darcy velocity The continuity equation can now be expressed as follows. Change the temperature until you get some separation in the direction you want. 5 Range of velocities 01-07 ftsec. However the graphical technique becomes very tedious when several solutes are present and must be considered.

Source: sciencedirect.com

Source: sciencedirect.com

Column cross section area Gas mass flow rate G 02778 16665 01667 Sqm Column dia 0461 m Thats it. The PackCol program performs hydraulic design and rating calculations for packed columns and towers. Transfer of absorbate molecules into the bulk. How to calculate limiting flow rates and column diameter 1. Absorber Tower An Overview Sciencedirect Topics.

Source: ebookreading.net

Source: ebookreading.net

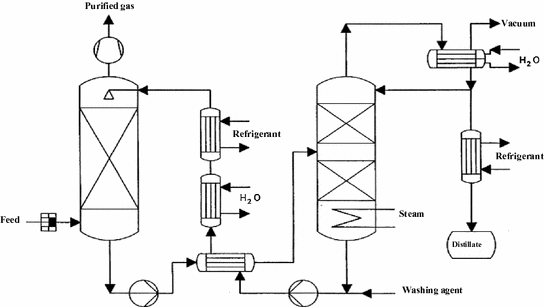

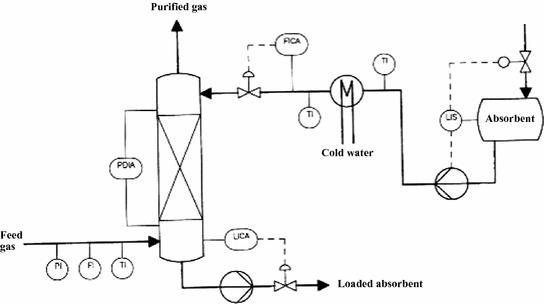

Mod-04 Lec-05 Tutorial – Part I Design of Absorption Column - YouTube. Absorption and stripping are conducted mainly in packed columns and plate columns trayed tower as shown in Figure 51-2. For an absorption column is the bottom stage. Hello Folks I am designing a CO2 absorption tower. Chapter 10 Staged And Packed Column Design.

Source: sciencedirect.com

Source: sciencedirect.com

You may start with these general guidelines and try to research the subject further to solve your problem. Put an adiabatic flash first. Simple Co2 Absorption Column Design - posted in Student. If the feed is not two phase at the desired pressure use an isothermal flash. A Concise Algorithm For Calculating Absorption Height In Spray Tower For Wet Limestone Gypsum Flue Gas Desulfurization Sciencedirect.

Source: sciencedirect.com

Source: sciencedirect.com

The PackCol program performs hydraulic design and rating calculations for packed columns and towers. Downcomer flooding should be avoided. 14 Examples for the design of packed columns 341 In absorption and desorption the total molar flow rate of vapour consisting of the carrier gas and the transfer components is given by V V Y where V Vu 1 - yu 14-24 and the total molar flow rate of liquid consisting of. 106-5 or 106-6 5. Packed Tower An Overview Sciencedirect Topics.

Source: link.springer.com

Source: link.springer.com

Y Partial pressure of so2total pressure. Arberor MITA Design groupELMAGERARD CALCULATION REPORT TECHNOLOGICAL AND CONSTRUCTION PROJECT EQUIPMENT ACETONE. Y Partial pressure of so2total pressure. Calculate ΔP flood 4. Absorption And Stripping Columns Springerlink.

Source: pinterest.com

Source: pinterest.com

Select a suitable G LG G ratio and a total gas flowrate 3. Mod-04 Lec-05 Tutorial – Part I Design of Absorption Column - YouTube. The absorption factor approach can be utilized either for hand or computer calculation. The equilibrium x y data are converted to mole ratio unit X Y and plotted on X-Y plane. Pin On Alternative Therapies.

Source: researchgate.net

Source: researchgate.net

14 Examples for the design of packed columns 341 In absorption and desorption the total molar flow rate of vapour consisting of the carrier gas and the transfer components is given by V V Y where V Vu 1 - yu 14-24 and the total molar flow rate of liquid consisting of. Transfer of absorbate molecules into the bulk. ACETONE ABSORPTION COLUMN CALCULATION REPORT TECHNOLOGICAL AND CONSTRUCTION PROJECT EQUIPMENT ACETONE ABSORPTION COLUMN Nomenclature. 32 Schematic of adsorption column L qA q flow rate u volumetric flux or Darcy velocity The continuity equation can now be expressed as follows. Pdf Design Of A Packed Bed Absorption Column Considering Four Packing Types And Applying Matlab.

Source: sciencedirect.com

Source: sciencedirect.com

To do this list the. Calculate ΔP flood 4. If the feed is not two phase at the desired pressure use an isothermal flash. Design of plate column for absorption and distillation involves many common steps of calculation such as determination of number of theoretical plates column diameter plate hydraulic design etcIn absorption process a soluble component is absorbed in a liquid called solvent from a gaseous mixture. Packed Tower An Overview Sciencedirect Topics.

Source: in.pinterest.com

Source: in.pinterest.com

Select a suitable packing material with F p random or structured 2. The primary objective is to determine the height and diameter of the column. If the feed is not two phase at the desired pressure use an isothermal flash. FACTORS TO BE CONSIDERED IN DESIGNING AN ABSORPTION COLUMN Minimum Liquid Flow Rate Gas Flow Rate Loading Point Flooding Point Pressure Drop Along Transfer Units in the column Optimum operating condition for the packed column is located between the. Lceted Institute For Civil Engineers Civil Engineering Civil Engineering Design Civil Engineering Construction.

DISTILLATIONABSORPTION COLUMN TRAY DESIGN ChE 4253 - Design I Tray Spacing. Fluid velocity larger than ascending bubbles minimum width. Most easiest way to design a packed absorption column. Put an adiabatic flash first. 2.

Source: link.springer.com

Source: link.springer.com

Arberor MITA Design groupELMAGERARD CALCULATION REPORT TECHNOLOGICAL AND CONSTRUCTION PROJECT EQUIPMENT ACETONE. Y Partial pressure of so2total pressure. The cure is slightly convex upward. Maybe calculating the Production Overhead Cost is the most difficult part of the absorption costing method. Absorption And Stripping Columns Springerlink.

Source: in.pinterest.com

Source: in.pinterest.com

Large if froth is expected also allow space for crawling 12 to 24. Maybe calculating the Production Overhead Cost is the most difficult part of the absorption costing method. Change the temperature until you get some separation in the direction you want. 14 Examples for the design of packed columns 341 In absorption and desorption the total molar flow rate of vapour consisting of the carrier gas and the transfer components is given by V V Y where V Vu 1 - yu 14-24 and the total molar flow rate of liquid consisting of. Least Density Of The Slab Should Be 125 Mm Absorption Of Water Should Not Be Over 15 Civil Engineering Civil Engineering Design Civil Engineering Books.

Source: youtube.com

Source: youtube.com

07022020 Due to receipt of continuous requests for the blower capacity hydraulic power estimation Flooding HETP calculations extending the post. How to calculate limiting flow rates and column diameter 1. Design of plate column for absorption and distillation involves many common steps of calculation such as determination of number of theoretical plates column diameter plate hydraulic design etcIn absorption process a soluble component is absorbed in a liquid called solvent from a gaseous mixture. Residence time criteria 3-5 sec. Mod 04 Lec 02 Packed Tower Design Part I Youtube.

Ii φ cc t u c x si 0 The independent variables can be made dimensionless. Put an adiabatic flash first. Design of plate column for absorption and distillation involves many common steps of calculation such as determination of number of theoretical plates column diameter plate hydraulic design etcIn absorption process a. Residence time criteria 3-5 sec. 2.

Source: youtube.com

Source: youtube.com

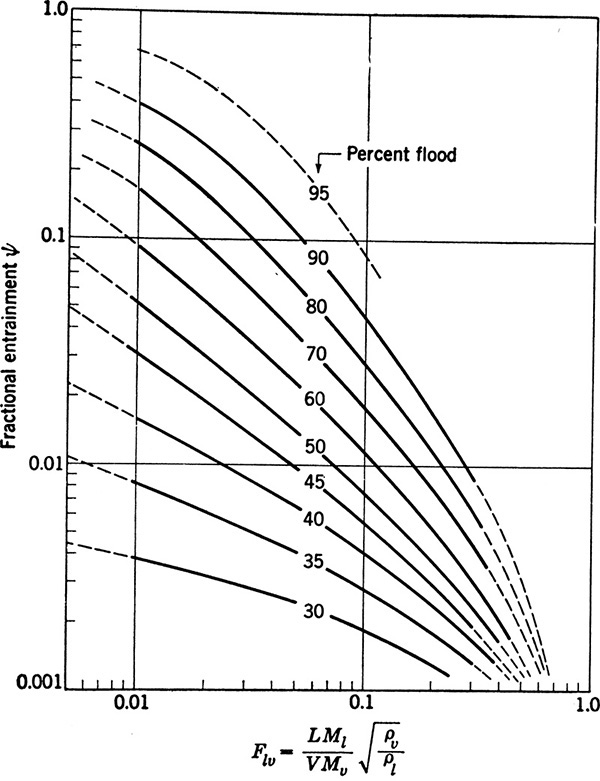

The calculation of column diameter for distillation and absorption columns h6 is usually based on the flooding velocity which in turn requires values of the flooding capacity factor Cf- Fair s flooding-capacity plot for sieve trays 1 correlates the flooding capacity factor with a flow parameter Flv for each tray-spacing value t as shown in Figure 2. The length of the packed bed column would be a function of the quantity mass of the molecular sieve required in the saturation zone of the packed column the selected bed diameter and the bulk density of the molecular sieve material. The equilibrium x y data are converted to mole ratio unit X Y and plotted on X-Y plane. 1 Allocation of Variable Manufacturing. Operation Of An Absorption Column Interactive Simulation Youtube.